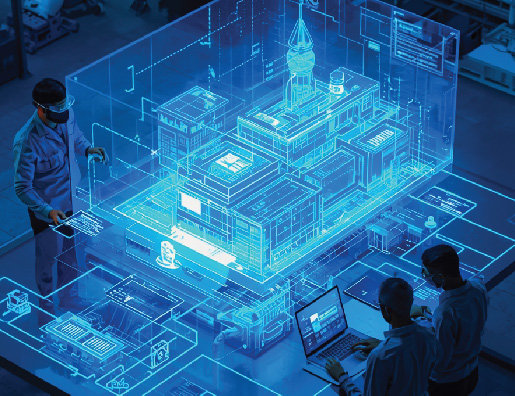

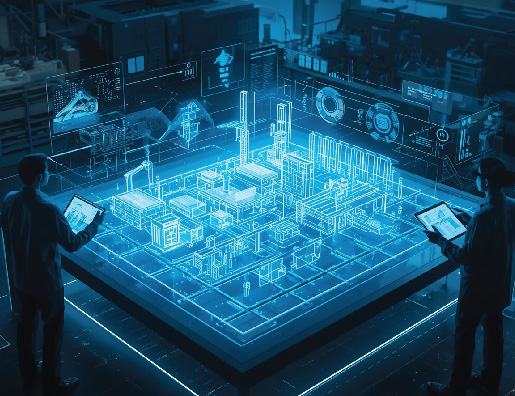

The industrial digital twin market is rapidly expanding due to the growing adoption of smart factories, Industry 4.0 technologies, and data-driven manufacturing. Companies can leverage digital twins to reduce operational costs, increase productivity, improve safety, and gain a competitive advantage in global manufacturing.